Why Choose VOLTER CNC

Routers for Aluminium?

Configure your CNC router

KEY FEATURES AND

BENEFITS:

- Engineered for 24/7 efficiency and precision machines for aluminium cutting

- Custom manufacturing to your requirements

- Wide range of configurations

- Warranty and post-warranty service

- Training for your specialists

VOLTER CNC ROUTERS

FOR ALUMINUM

PROCESSING

High Precision and Performance

for Complex Tasks

Video

For aluminium processing, we recommend our VOLTER L and VOLTER SX models. Both are equipped with high-speed spindles and powerful drives, ensuring high performance and precision in processing.

The L-Series offers working areas ranging from 1,610x1,610 mm to 8,200x2,150 mm, making it ideal for handling large workpieces and executing large-scale projects. Its robust capabilities make it an excellent choice for ambitious manufacturing operations.

The SX-Series, small but strong, with a working area of 1,020x1,200 mm, is perfect for producing small to medium-sized parts. Its compact yet powerful design ensures precision and efficiency, making it suitable for detailed work and intricate designs.

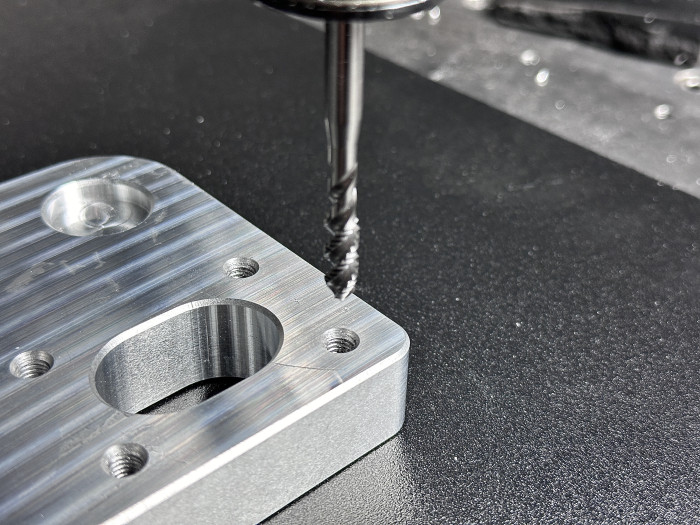

Both machines can process aluminium up to 100 mm thick, providing a versatile solution for a wide range of manufacturing tasks. Whether you are working on large structural components or small intricate parts, VOLTER CNC routers deliver the accuracy and efficiency needed for high-quality aluminium processing.

BASIC CONFIGURATION

ROBUST CONSTRUCTION

Our CNC routers feature a sturdy, thermal welded steel frame, ensuring stability and durability even under heavy usage conditions.

SECURE MATERIAL HANDLING

The vacuum table securely holds any material in place, preventing any shifting. Additionally, the laser pointer aids in precisely positioning the material on the work surface.

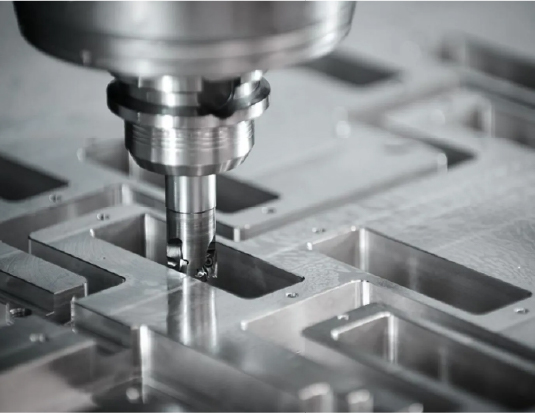

POWERFUL SPINDLES

With spindle power ranging from 4.5 to 16 kW, air-cooled and water-cooled, our routers guarantee high performance and superior processing quality.

USER-FRIENDLY CONTROL

The touch monitor and handheld controller simplify machine operation, making it user-friendly and convenient.

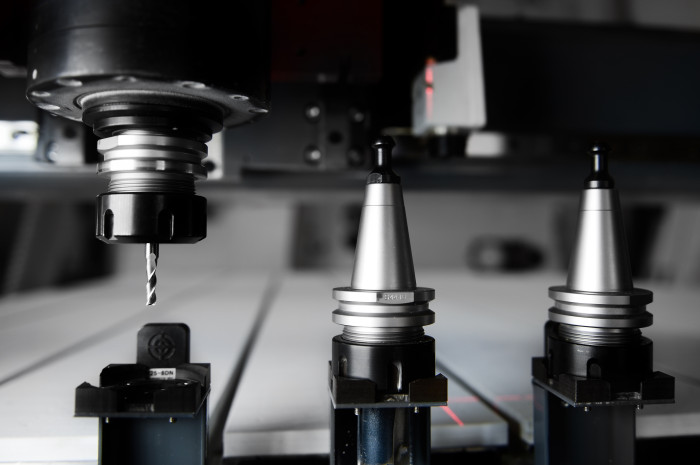

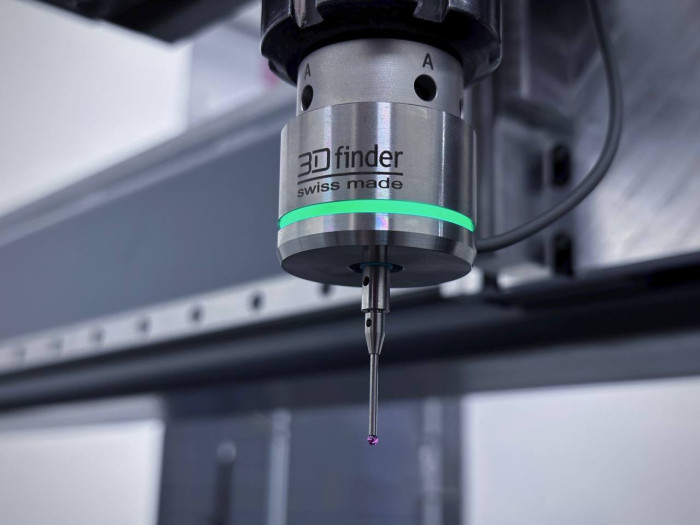

TOOL LENGTH SENSOR

The sensor allows the exact measurement of the length of the bit quickly and accurately. Results of this measurement will be saved in the controller, which prevents damage to the working surface of the machine.

SMOOTH AND PRECISE MOVEMENT

Helical racks and servo drives ensure smooth and accurate movement, minimizing vibrations and improving the final product quality.

CASE STUDIES

EcoCycle, a leading bicycle manufacturer in the Netherlands, purchased a VOLTER L6020 CNC router with an automatic tool changer and Pneumatic Locator Pins (PLP) System for aluminium processing. Their spokesperson said, "Unlike the Chinese machines we used before, the VOLTER router has worked perfectly for over 7 years, running about 20 hours a day. Our production efficiency went up by 40%, and our defect rate dropped by 31%. We are very happy with the quality and reliability of VOLTER equipment."

EcoCycle

Netherlands

AeroParts, a company from Spain that makes parts for the light aviation industry, shared their experience: "Our old machine often broke down, causing production delays. After buying a VOLTER CNC router, we can now process aluminium parts with high precision and no interruptions. The quality of our parts has greatly improved, and our clients are happy with the faster delivery times. The new VOLTER equipment has given us the stability and reliability we needed. This investment has fully met and even exceeded our expectations."

AeroParts

Spain

GreenHomes, a Finnish company that makes eco-friendly homes, started using CNC machines recently. "Before, threading and drilling aluminium panels by hand was a big challenge for us. It took a lot of time and effort. With the VOLTER CNC router, everything changed. Now, making one part is 8 times faster. Our workers can focus on more important tasks, and our production has grown a lot. The CNC router has exceeded all our expectations and made our production much more efficient. Thank you for the excellent equipment!"

GreenHomes

Finland

TESTIMONIALS

Woodmen & Tree is a Belgian furniture brand. We design both wooden furniture and accessories. You can discover influences of mid-century modern, Scandinavian and Japandi in our designs.

We use our Volter CNC for nesting. We start with a wood veneer panel, and use our CNC to divide the panel into smaller pieces, drilling holes and cutting didos, all within one single step. This saves us a massive amount of time.

Volter is one of the few European companies that builds this type of modern CNC machine. Most other European brands only offer colossal and unaffordable big CNC machines that are out of reach for a company like ours.

The Volter L3016 is very versatile and extremely well built, you get a lot of value for its price. It has advanced features like an automatic tool changer, segmented vacuum table and a laser for quick alignment. Also, it's easy and intuitive to work with.

Pieter Delbeke

Belgium

The Volter L2016 machine was purchased by our company at the beginning of 2020. And already in June 2020, it was delivered and installed in our production. Since then, it has been used 2 days a week, with a time interval of 6 to 8 hours a day. Our company specializes in the production of measuring trolleys for determining the geometric parameters of rail tracks. We use Volter equipment mainly for the production of prototypes and preparing them for further testing of our products, as well as for the manufacture of smaller elements.

A large variety of tools, fast and easy operation of the machine, as well as its ease of maintenance are crucial for our needs. Speaking about the comfort of use, I would like to note that it is very convenient to have a built-in vacuum cleaner that will immediately remove the chips left after cutting. Due to the large working surface area, we can cut plates of any size without any problems.

We are very pleased with our decision to buy a Volter machine.

Veronika Káplová

Czech Republic

The main activity of the Alu Enterijer company is production of doors and windows from PVC and aluminium. We planed to expand our business with production of facades from aluminium composite panels. VOLTER ACP4020 CNC Router was installed in our workshop in November 2017. The machine allows to produce a large number of facade cassettes every day with high speed and accuracy.

Our plan is to become a leader in the processing of aluminium composite panels in our region. At the presentation of the VOLTER machine in Kolin city, we were satisfied with the speed and quality of cutting, efficient vacuum table and design of the machine. Also we liked heavy steel frame and reasonable price.

Milovan Jovetic

Serbia

We are a full service POP communication agency with own production established in 1993.

In the production of P.O.P.A. products we process various kinds of materials from plastic, polystyrene, wood, Dibond to cardboard. Our values are speed, quality, trust and creativity, which allows us to fulfill the VOLTER CNC machine to the last point.

Aleš Krupička

Czech Republic

Our company has been producing various advertising structures, from small signs to roof installations, free-standing steles, building facade linings for more than twenty-five years.

Now we have three Volter machines of different configuration in our production. We bought the first of them in 2013. We liked him. It still works without problems. Then we bought two more.

Among the main advantages, I would like to note the high accuracy and reliability of the equipment, the possibility of its operation 24/7. Simplicity and convenience of management are also important for us, as well as decent service support from the representative of Volter in Russia - Neotek company.

Xstream Company

Russia

ADVANTAGES OF OUR MACHINES

Our CNC routers ensure reliable and efficient performance, making them an excellent choice for diverse industrial applications.

High Precision and Quality

VOLTER CNC routers deliver exceptional accuracy and top-notch processing quality. They can perform a wide range of operations, including milling, cutting, creasing, drilling, boring, and engraving.

Versatility and Adaptability

These machines are versatile and can be easily adapted to meet various production requirements.

Durable Construction

With a robust design and the use of high-quality components, our machines boast a long service life. They can operate continuously 24/7 without the need for component replacement and very minimal maintenance.

Custom Configurations

We offer the possibility of customized equipment configurations, allowing you to tailor the machine to your specific production needs.

Our CNC routers ensure reliable and efficient performance, making them an excellent choice for diverse industrial applications.

OPTIMIZED FOR ALUMINIUM

Aluminium is widely used in industries such as aviation, automotive manufacturing, and furniture production due to its light weight and strength. This material allows for the creation of complex-shaped parts and diverse sizes, making it a popular choice for numerous applications.

VOLTER CNC routers are ideal for aluminium processing, providing high-quality and precise machining. Our routers are equipped with high-speed spindles and powerful drives, allowing for fast and efficient aluminium processing with minimal effort. They can perform operations such as milling, cutting, creasing, drilling, boring, 3D processing and engraving, significantly enhancing productivity and saving time.